With the rapid development of artificial intelligence, intelligent manufacturing is also developing rapidly through continuous exploration and research. We can see the application of artificial intelligence in industry in many scenarios, such as intelligent logistics sorting centers, industrial intelligent consoles, etc. Industry 5.0 has become a new chapter in the field of intelligent manufacturing, which combines human wisdom and machine efficiency. Performance, through technology we couldn’t have imagined, creating an unprecedented factory environment. Sandbox simulation provides us with an innovative way to allow students to experience the charm of Industry 5.0 first-hand and explore the cutting-edge areas of future manufacturing.

Why conduct Industry 5.0 sandbox simulation?

In the Industry 5.0 sandbox simulation, students can build a real factory scene and simulate various intelligent equipment, Internet of Things technology and human-machine collaboration systems, thereby showing the full picture of future industrial production. Through sandbox simulation, students can witness intelligent robots working closely with human workers to efficiently complete various tasks; intelligent sensors monitor the production process in real time, warn of failures and make optimization adjustments; and human creativity and decision-making capabilities will become the key to Industry 5.0. Core driving force.Industry 5.0 sandbox simulation not only helps companies optimize production processes and improve efficiency, but also provides valuable training opportunities for students. By participating in the sandbox simulation, they can experience the operation of future factories immersively, learn to work with smart equipment, improve their skills, and adapt to the emerging industrial environment.

So how to conduct Industry 5.0 sandbox simulation?

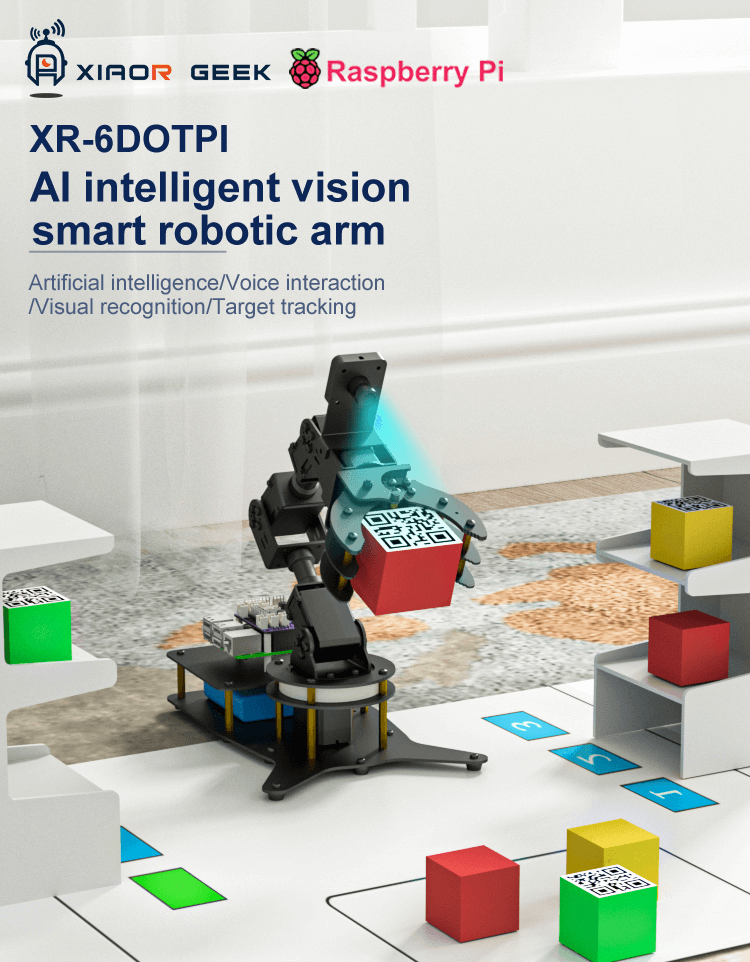

First of all, you must have such a device to perform simulated operations. It must not only satisfy the need for hand-eye control, but also be capable of intelligent sorting and palletizing.Then this Raspberry Pi AI smart robotic arm may be able to meet these requirements. In addition to meeting Industry 5.0 sandbox simulation, it can also be applied to training scenarios such as smart logistics and smart factories.

We can first take a look at what AI functions it has:

AI machine vision-sorting and palletizing

First-view FPV real-time picture: The robotic arm supports WiFi or wired connection. It can connect to WiFi hotspot signals when it is powered on, and can transmit the first vision on the robotic arm back to the software.Face recognition following: The 1080P high-definition camera equipped with the robotic arm recognizes and follows human faces, and can automatically adjust posture to keep the human face within sight.

Color recognition and following: You can specify the corresponding color. After the robot arm recognizes the corresponding color, it can locate the target and follow it.

Gesture recognition: The robotic arm can recognize gestures within the field of view. When different gestures are recognized, the software will automatically display the number corresponding to the gesture.

Color sorting: The robotic arm can identify and sort building blocks of different colors. In addition to the set colors, you can also develop and identify various custom colors by yourself.

QR code sorting: The robotic arm can identify different QR codes and determine the position of the QR code blocks, thereby realizing intelligent palletizing and stacking.

AI advanced vision-smart warehousing

Intelligent warehousing: The robot arm can find the type of block dragged on the software in the recognition area, and after successful recognition, it will automatically grab the wooden block and put it in the designated warehouse.

Intelligent warehouse transfer: The robotic arm can automatically move to the warehouse level number set on the software, and automatically grab the building blocks into the designated warehouse

In addition to some of the above AI smart functions, if you also want to make the robotic arm more intelligent, such as voice interaction, then you only need to add a voice block to control the robotic arm through voice to complete object following, transfer etc smart action.